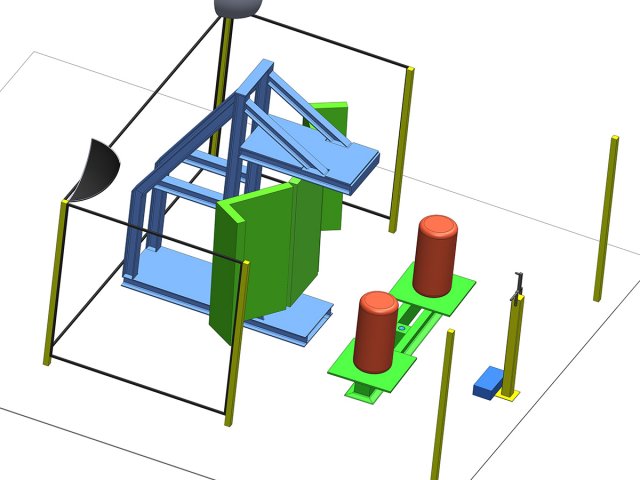

Special mould carriers

These are mould carriers usually built for only one specific project at the client’s request or for an application requiring special carrier functions.

- For example, these mould carriers are used for punching tools, preheating and forming tools, prototype and small series tools (such as semi-automatic control).

- For example, they can be characterised by an extra closing force, a large lift for the lower clamping table or the upper table can be mobile.

- The carrier can be equipped with both the lower and upper table pivoting towards the operator.

- All movements can be electrically controlled – for example, this solution is suitable the medical industry.